-

![Denizlerde Güvenle Yol Alın]() Denizlerde Güvenle Yol AlınMarine ve Offshore Sertifikalı

Denizlerde Güvenle Yol AlınMarine ve Offshore Sertifikalı -

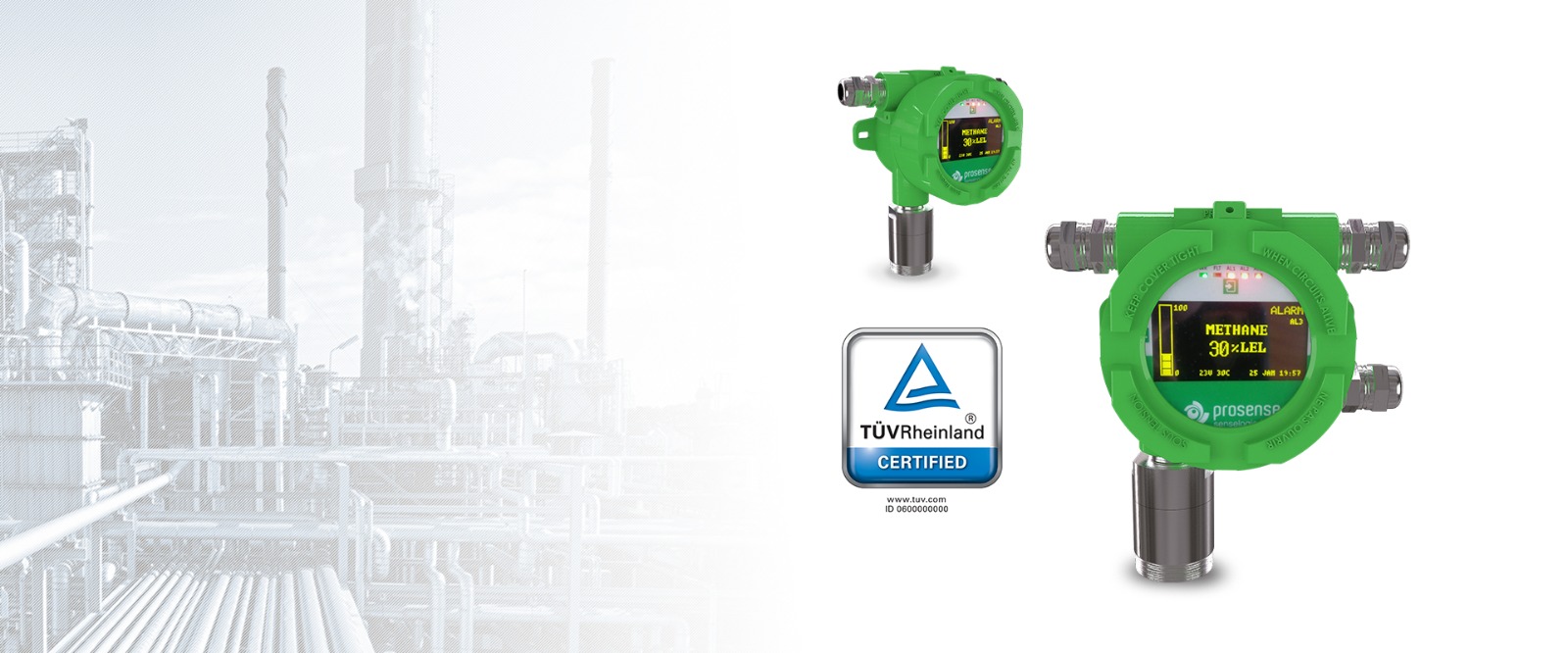

![Prosense Hidrokarbon Gaz Dedektörü]() Prosense Hidrokarbon Gaz DedektörüMPS™ sensörleriyleHidrokarbon tespitinde doğruluk ve güvenilirliği yeniden tanımlıyor!

Prosense Hidrokarbon Gaz DedektörüMPS™ sensörleriyleHidrokarbon tespitinde doğruluk ve güvenilirliği yeniden tanımlıyor! -

![Prosense ile Hassas Ölçüm]() Prosense ile Hassas ÖlçümVOC Riskini AzaltınPQD VOC Gaz Dedektörleri

Prosense ile Hassas ÖlçümVOC Riskini AzaltınPQD VOC Gaz Dedektörleri -

![Prosense HART iletişim modülü ve yazılımı FDI tarafından tescil edildi.]() Prosense HART iletişim modülü ve yazılımı FDI tarafından tescil edildi.

Prosense HART iletişim modülü ve yazılımı FDI tarafından tescil edildi. -

![Kalibrasyon Bakım Hizmeti]() Kalibrasyon Bakım HizmetiTÜRKAK AKREDİTEKalibrasyon hizmetlerimiz 10.12.2021 tarihi itibariyle Türk Akreditasyon Kurumu (TÜRKAK) tarafından TS EN ISO/IEC 17025 Standardı kapsamında AB-0260-K no ile akredite edilmiştir.

Kalibrasyon Bakım HizmetiTÜRKAK AKREDİTEKalibrasyon hizmetlerimiz 10.12.2021 tarihi itibariyle Türk Akreditasyon Kurumu (TÜRKAK) tarafından TS EN ISO/IEC 17025 Standardı kapsamında AB-0260-K no ile akredite edilmiştir. -

![PQ Serisi Gaz Dedektörleri]() PQ Serisi Gaz DedektörleriSIL2, SIL3 SERTİFİKALI

PQ Serisi Gaz DedektörleriSIL2, SIL3 SERTİFİKALI -

![Soma Maden Gaz Dedektörü]() Soma Maden Gaz DedektörüM1 SertifikalıSoma gaz dedektörleri; çalışanları madenlerdeki gaz tehlikelerine karşı korumak için tasarlanmıştır. SOMA gaz dedektörleri madencilerin hayatını kurtarıyor!

Soma Maden Gaz DedektörüM1 SertifikalıSoma gaz dedektörleri; çalışanları madenlerdeki gaz tehlikelerine karşı korumak için tasarlanmıştır. SOMA gaz dedektörleri madencilerin hayatını kurtarıyor! -

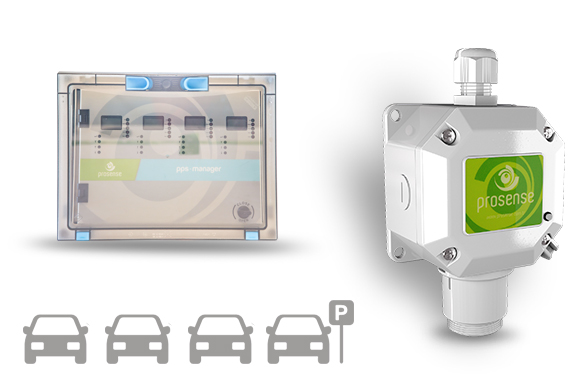

![Kapalı Otoparklarda Gaz Algılama]() Kapalı Otoparklarda Gaz AlgılamaEN-50545-1 SERTİFİKALI PROSENSE PPS+

Kapalı Otoparklarda Gaz AlgılamaEN-50545-1 SERTİFİKALI PROSENSE PPS+

Gaz Dedektörleri

Geniş ürün yelpazesine sahip olan Prosense birçok uygulamayı kapsayan gaz algılama sistemleri üretmektedir. 1000’den fazla endüstriyel gaz için, gaz detektörleri ve gaz kontrol panelleri üreten Prosense, ürünlerin ve üretim süreçlerinin kalitesini uluslararası sertifikalar ile belgeledirmektedir.

Mühendislik Birikimi ve Sektörel Tecrübe

Kütüphanemizde bir yolculuk yapın ve deneyimlerimizden yararlanın.

· Gaz Algılama Prensipleri

· Sensör Teknolojileri

· Standartlar ve Sertifikalar

· Web seminerleri

· Gaz Detayları

· Ekipman İncelemeleri

Daha fazlasını öğrenmek istiyorsanız, lütfen bize sormaktan çekinmeyin.

28 Temmuz Perşembe günü 15:00-16:00 saatleri arasında Prosense Akademi öncülüğünde sektörel ...

Devamı

Bu yazımızda alev dedektörleri hakkında bilgi edinebilirsiniz. Aşağıdaki soruların cevaplarını bulabilirsiniz. Alev ...

Devamı

26 Ocak Perşembe günü 15:00-16:00 saatleri arasında Prosense Akademi öncülüğünde sektörel ...

Devamı

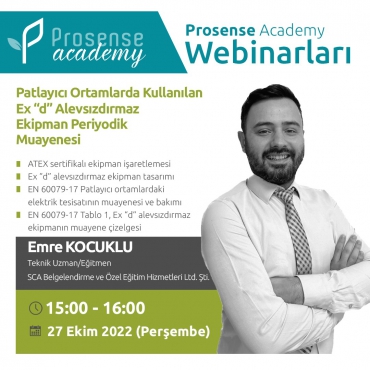

27 Ekim Perşembe günü 15:00-16:00 saatleri arasında Prosense Akademi öncülüğünde sektörel ...

Devamı

24 Kasım Perşembe günü 15:00-16:00 saatleri arasında Prosense Akademi öncülüğünde sektörel ...

Devamı29 Eylül Perşembe günü 15:00-16:00 saatleri arasında Prosense Akademi öncülüğünde sektörel ...

Devamı

25 Ağustos Perşembe günü 15:00-16:00 saatleri arasında Prosense Akademi öncülüğünde sektörel ...

Devamı

26 Nisan Salı günü 15:00 - 16:00 saatleri arasında yapılacak "Proses ...

Devamı

29 Mart Salı günü 15:00 - 16:00 saatleri arasında yaptığımız "Gaz ...

Devamı