As a Zone 2-Category 3 device, the PC3-3412 Propane gas detector is designed for continuously monitoring Propane in the light industrial areas.

High-quality catalytic sensor in PC3-3412 shows excellent results in 0-100%LEL range.

• Sensor: Uses high-quality catalytic sensor to detect Propane gas in 0-100%LEL range.

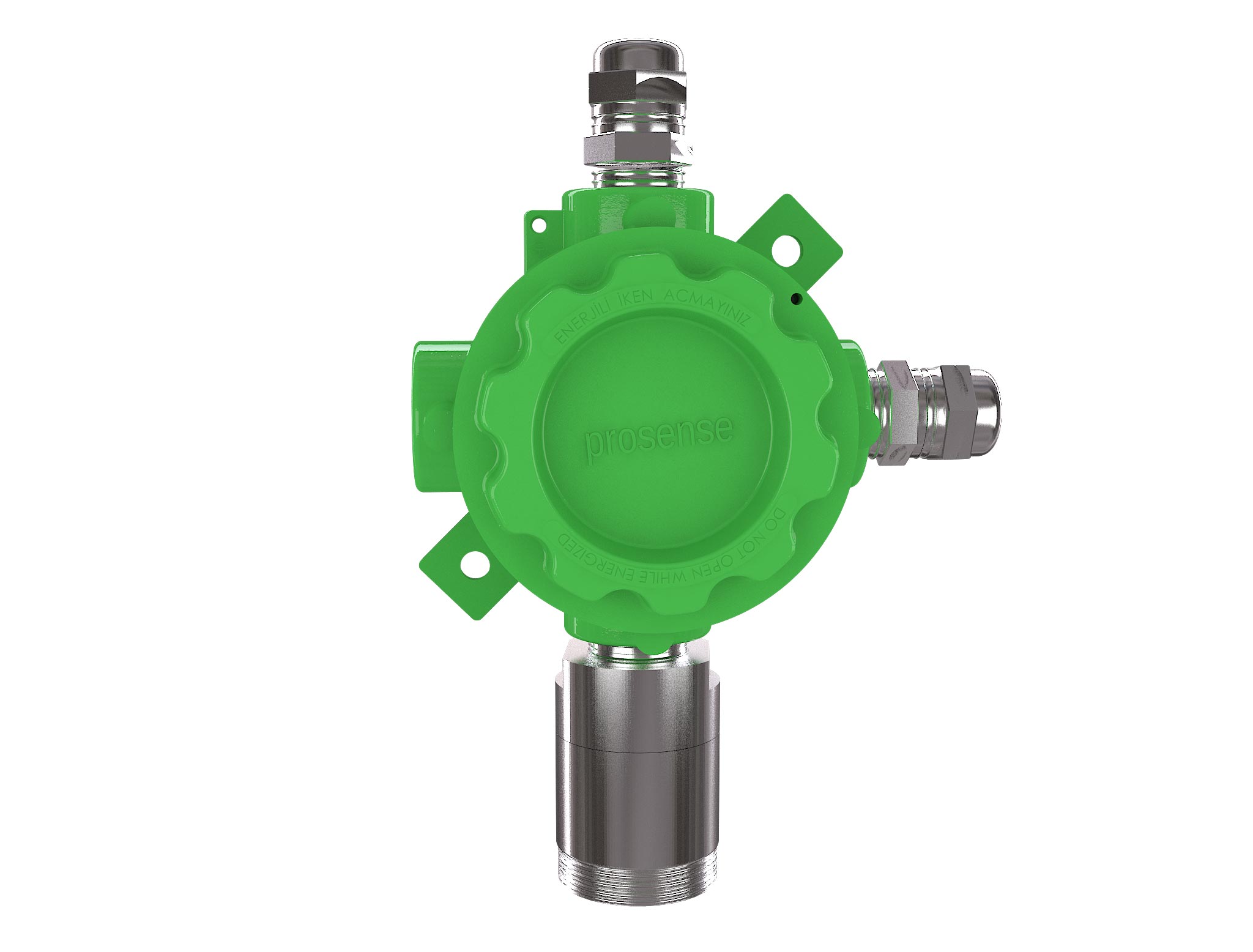

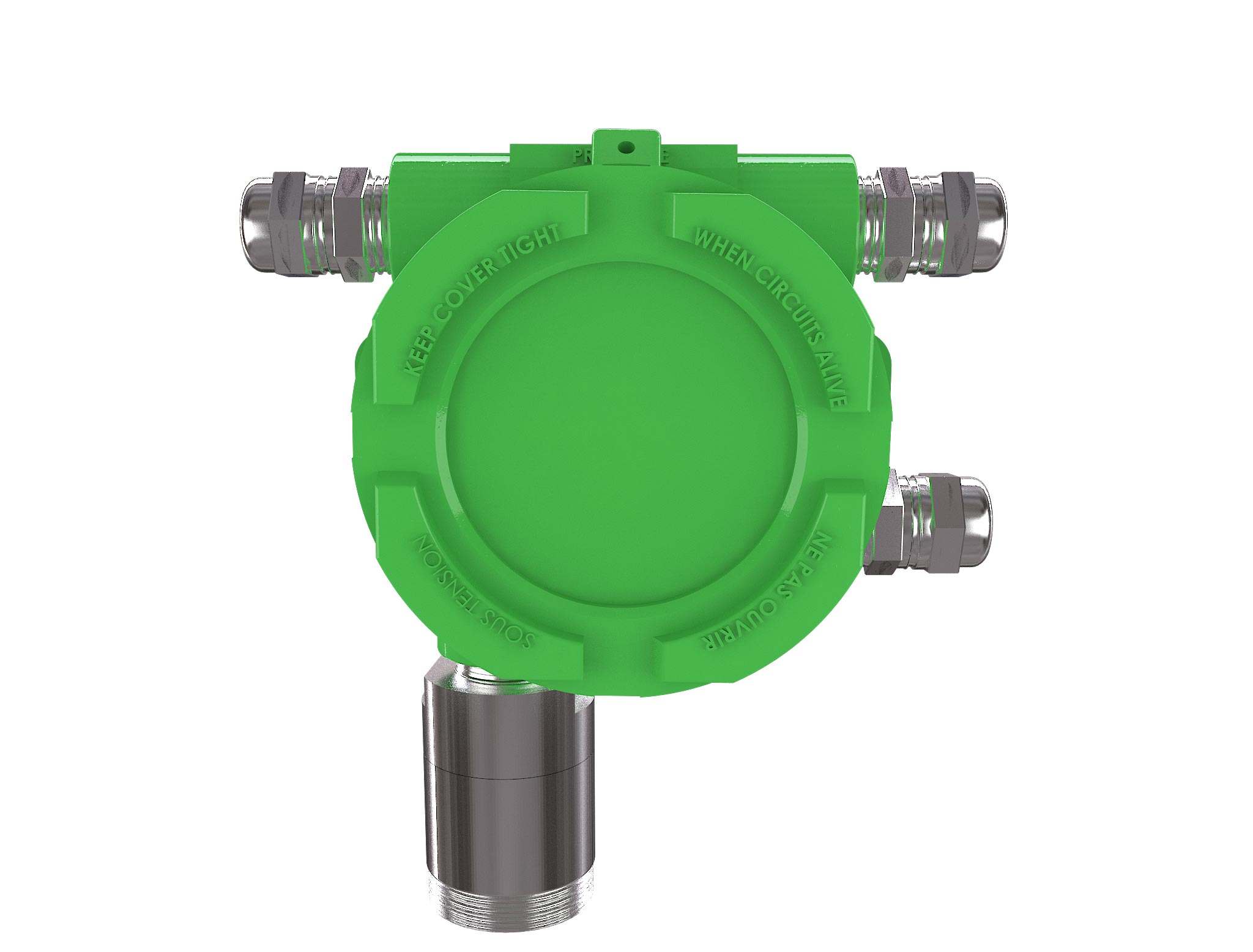

• Connection: Provides universal output 4-20mA and Modbus RS485

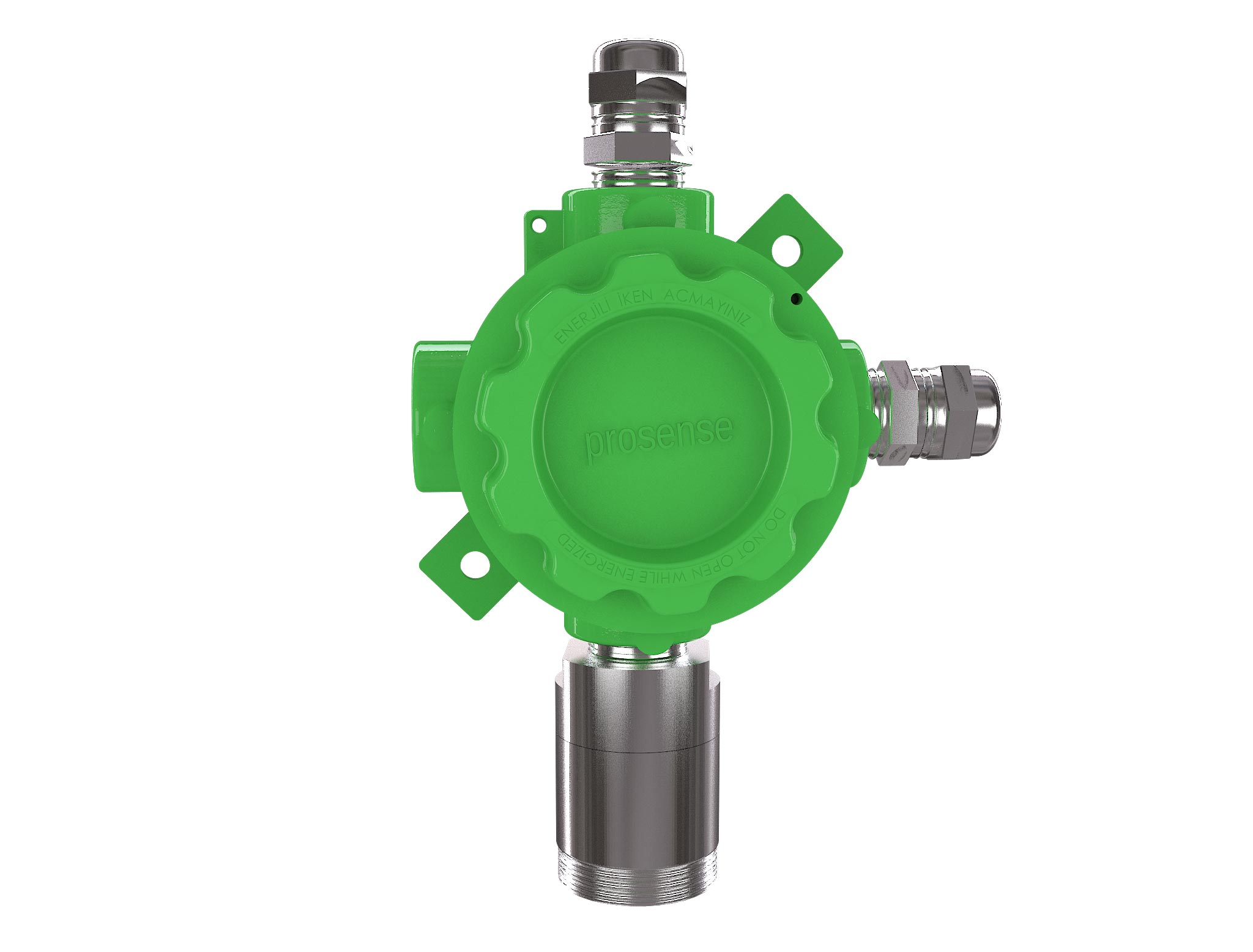

• Entry: 1 x 1/2″ NPT cable entry

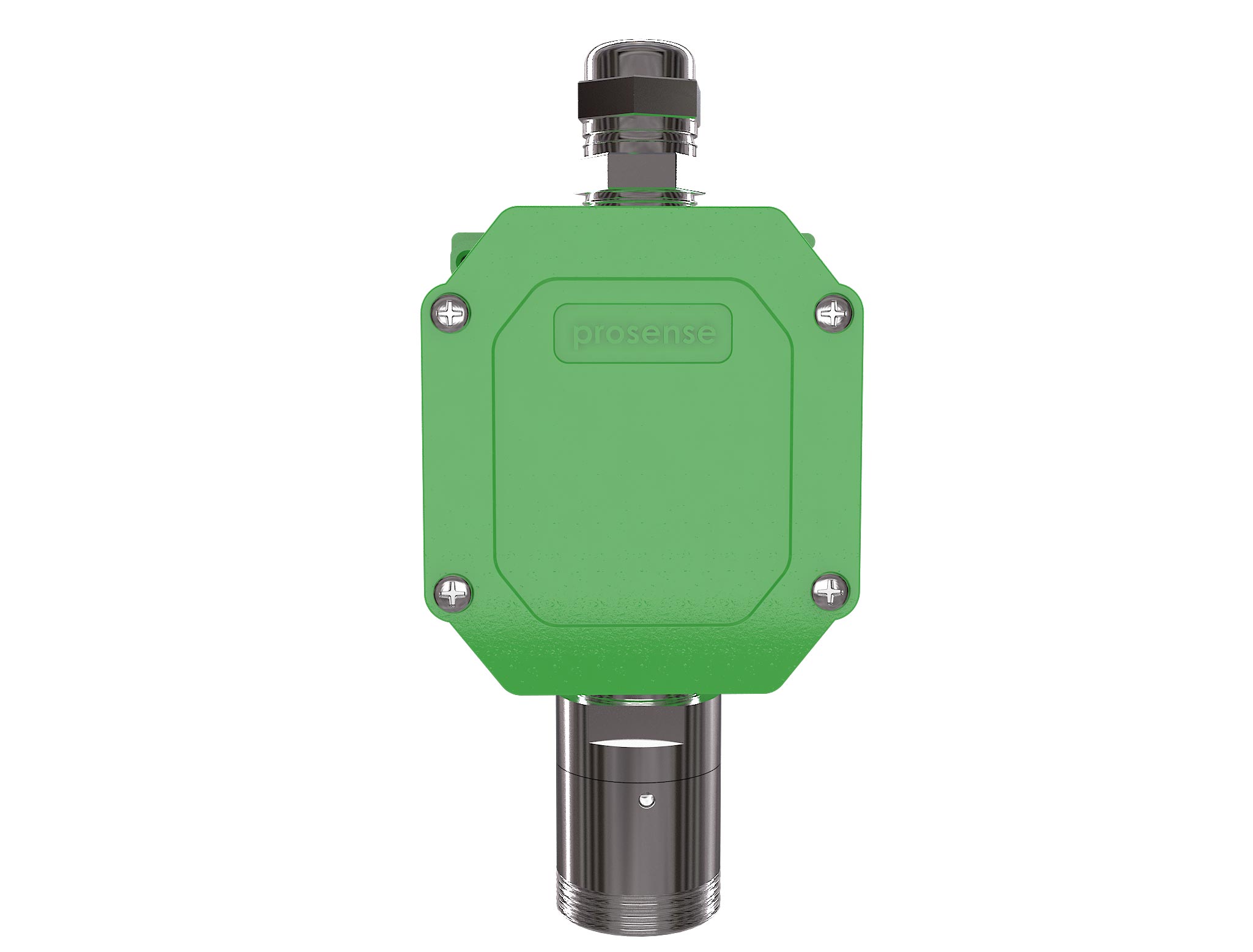

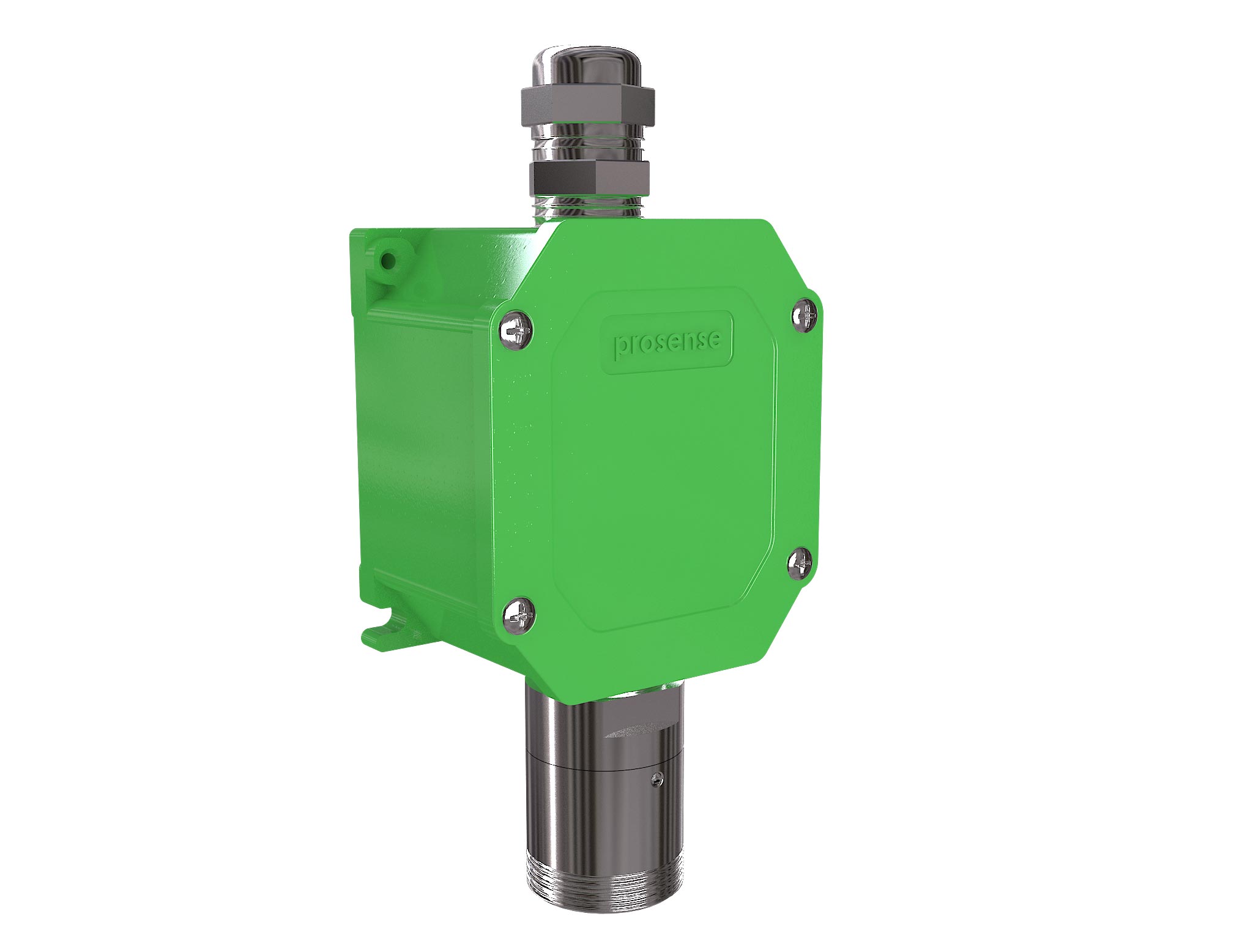

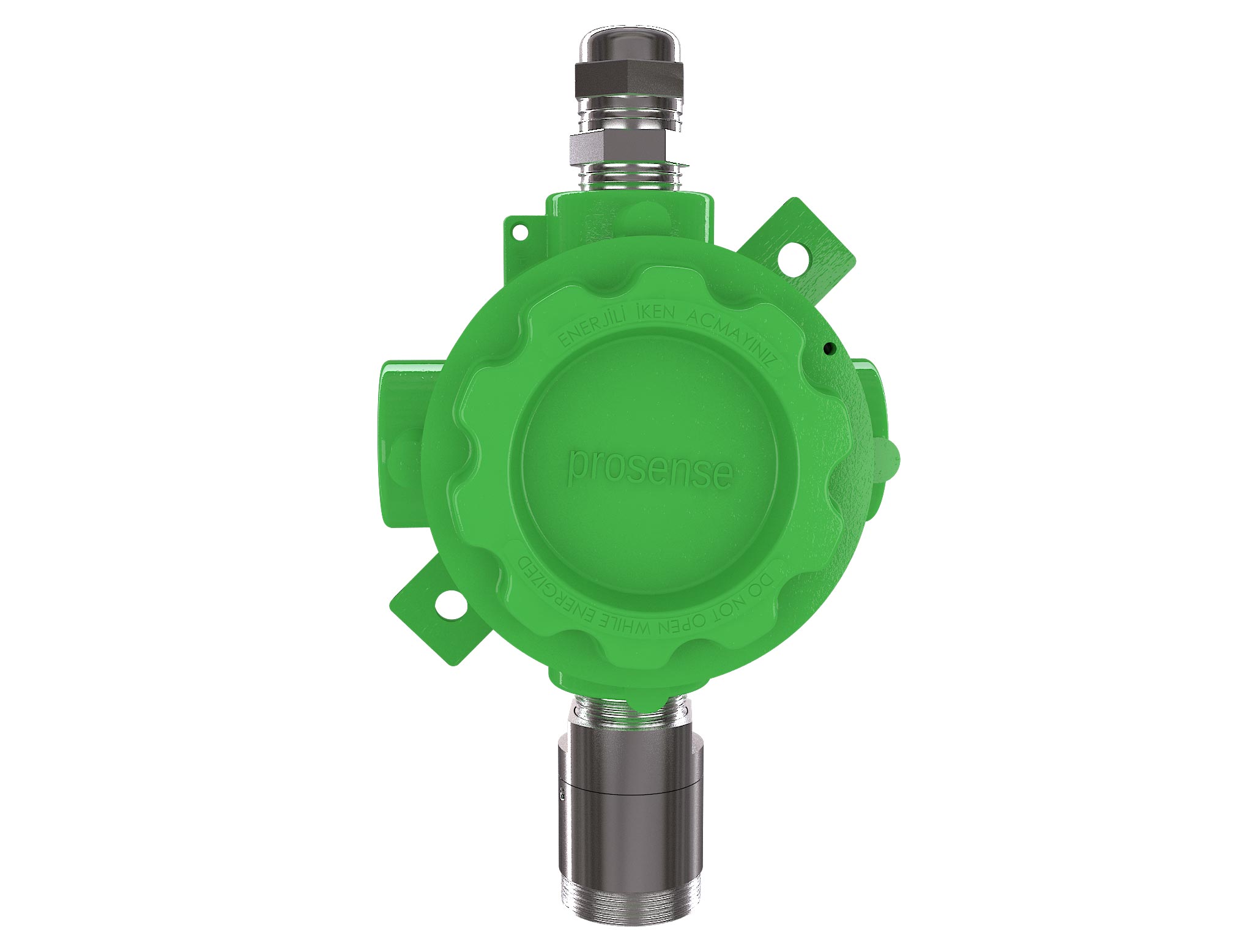

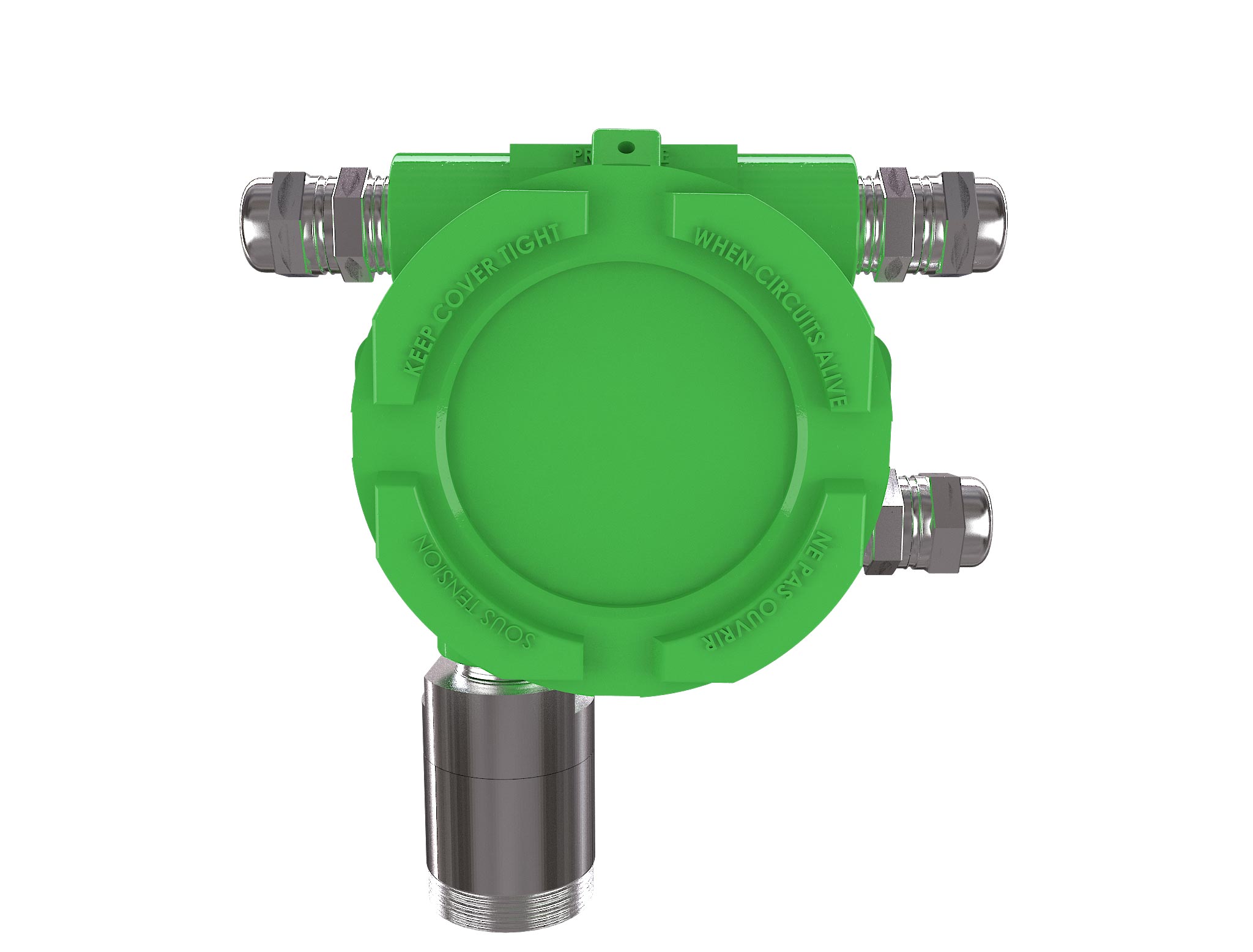

• Body: Aluminium die-cast body and sensor head superb performance under harsh environmental conditions with IP65 protection class.

• Remote Control: Detector status can be monitored through Prosense Gas Monitoring software remotely.

• Modbus: Easy to integrate into SCADA systems via open-source Modbus RS485(RTU) codes

• Relay Contacts: 2 Alarm, 1 Fault relays can be set predefined levels and they can manage the other devices like a siren, a beacon in case of any event.

| Sensor Technology | Catalytic |

| Output Signal | 4-20mA Analog Modbus RS485 RTU |

| Sensor Warm-Up | 60sec |

| Response Time(T90) | <25sec |

| Accuracy | %±1 |

| Operating Temperature | ‐20°C ~ +50°C |

| Humidity | 5 ~ 95%RH Non-Condensing |

| Input | Min 10VDC - Max 32VDC - Nominal 24VDC |

| Power Consumption | Max.2W |

| Relay Outputs | 2 Alarms (Selectable), and 1 Fault (All relays are NO/NC adjustable) |

| Cable Entry | 1x 1/2"NPT |

| IP Rating | IP65 |

| Junction Box | Epoxy Painted Die‐cast Aluminium |

| Sensor Head | Nickel‐plated Brass |

| Dimensions/Weight | 190x110x70mm / 810gr |

| Standards | EN 60079‐0 EN 60079‐1 EN 60079‐18 |

| Hazardous Class | Zone 2 ‐ Category 3 |

PC3 Datasheet

PC3 User Manual